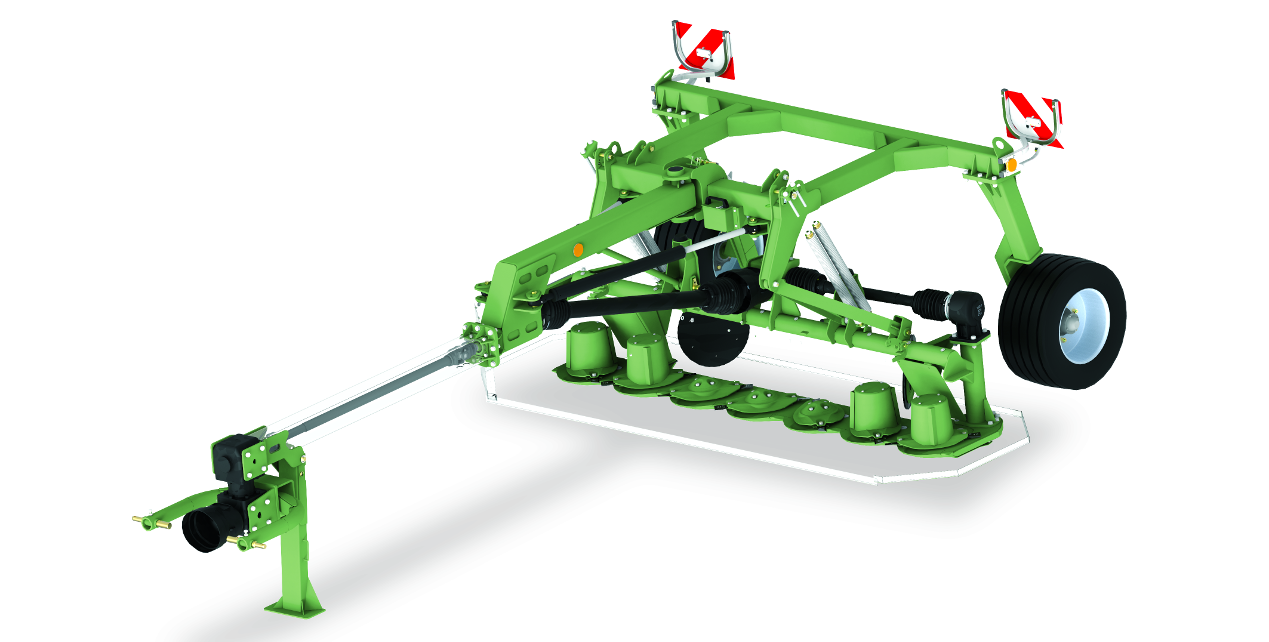

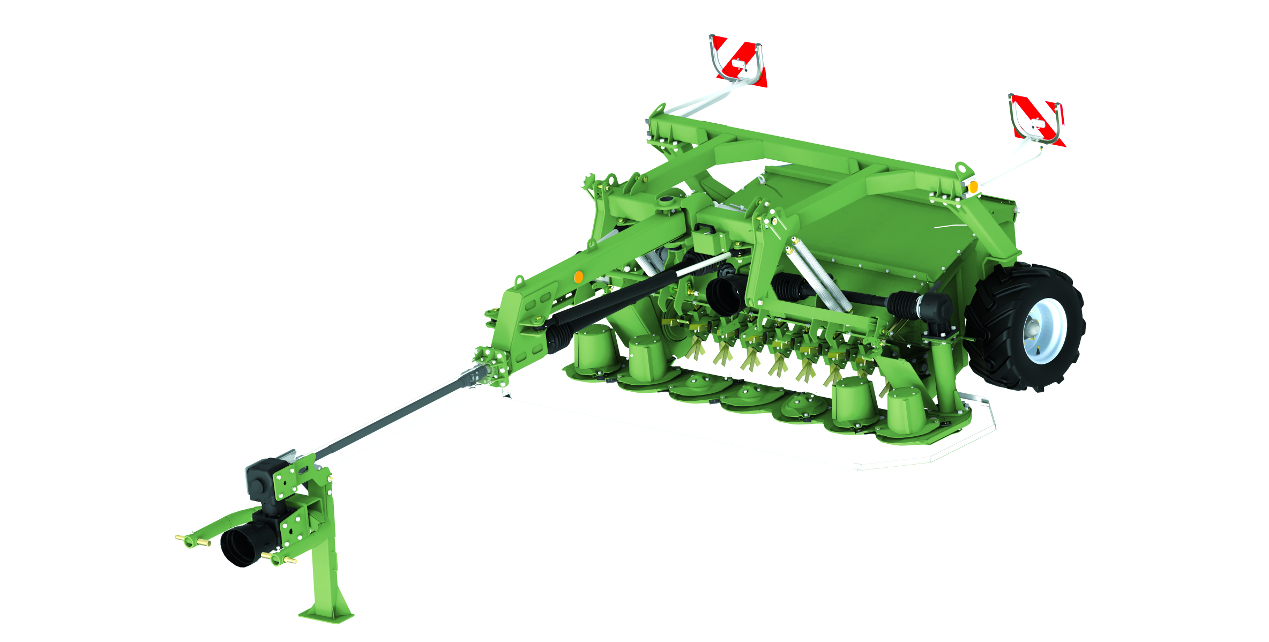

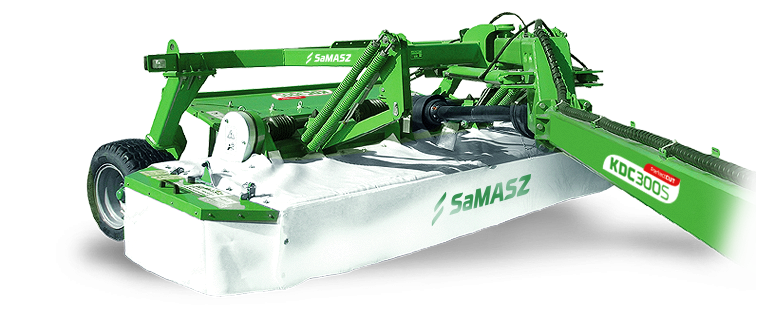

KDC - trailed

Our design of trailed mowers with central drawbar allows working on both sides of the tractor. It helps to save time when taking turns. KDC mowers can be additionally equipped with tine or roller conditioner and belt conveyor for swath transportation.

- stapless regulation of cutting height (from 4,5 cm to 7 cm)

- use of topping plates possible (increases cutting height to 6 cm - 9 cm)

or double topping plates (increases cutting height to 8 cm - 12 cm) - perfect ground following also on uneven and steep terrain

- lower pressure on the ground thanks to road wheels

- eliminates tedding thanks to application of conditioners - saves time of fodder collection

- hydraulic lifting for headlands and transport

- mechanical transport locking - foldable side guards for comfortable transport

- foldable side guards for convenient transport

- KENNFIXX hydraulic connector

- change of rpm possible by reversing main gearbox by 180°

- wide wheels for stability during transport

- easy forming of swath with swath guides

- low operating costs

- most of maintenance works to be done on user’s own

- more than 25 years of experience in manufacturing disc mowers

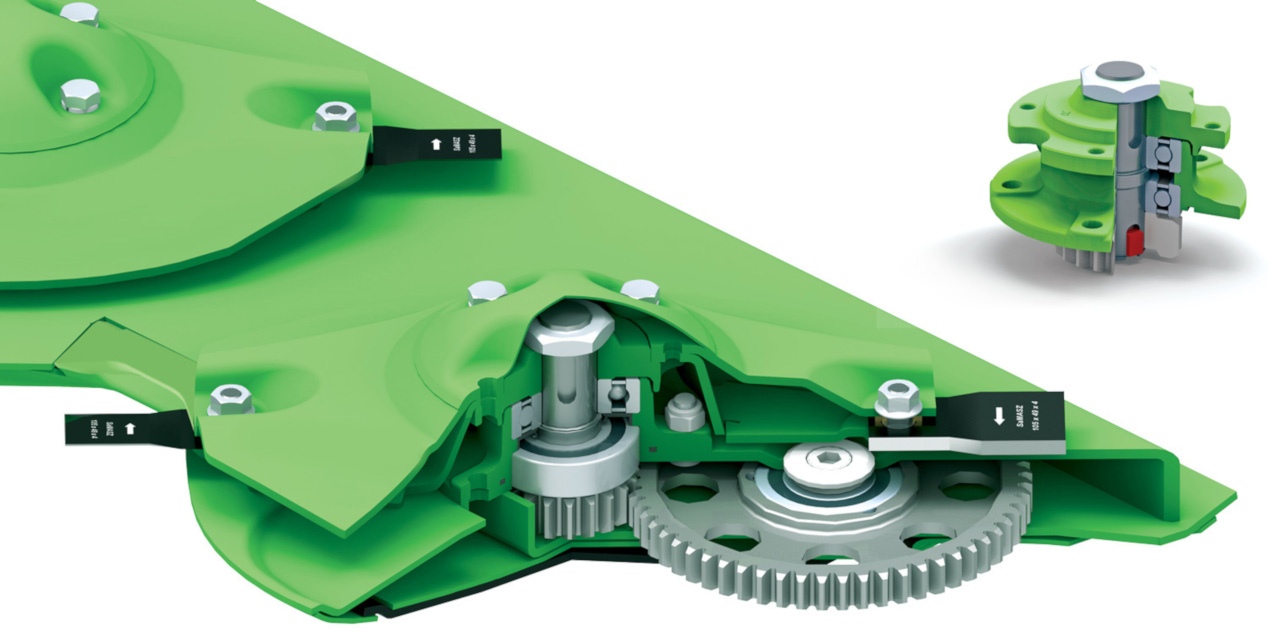

- own design of PerfectCUT cutterbar tested on markets across the world

- 2-year warranty

- more than 800 KDC mowers working on fields across the world

| KDC 300 | KDC 340 | KDC 390 | KDC 430 | KDC 300 S | KDC 340 S | KDC 300 ST | KDC 340 ST | KDC 301 W | KDC 341 W | KDC 301 WT | KDC 341 WT | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working width | [m / ft] | 3,00 / 9’10” | 3,40 / 11’2” | 3,90 / 13’ | 4,30 / 14' | 3,00 / 9'10" | 3,40 / 11’2” | 3,00 / 9’10” | 3,40 / 11’2” | 3,00 / 9’10” | 3,40 / 11’2” | 3,00 / 9’10” | 3,40 / 11’2” |

| Transport width | [m / ft] | 3,00 / 9’10” | 3,40 / 11’2” | 3,90 / 13’ | 4,30 / 14’ | 3,00 / 9'10" | 3,40 / 11’2” | 3,00 / 9’10” | 3,40 / 11’2” | 3,00 / 9’10” | 3,40 / 11’2” | 3,00 / 9’10” | 3,40 / 11’2” |

| Swath width | [m / ft] | ~1,20 - 1,50 / ~3'11" - 4'11" | ~2,20 - 2,50 / ~7'2" - 8'2" | ~2,50 - 2,70 / ~8'2" - 8'10 | ~2x 1,20 - 1,30 / ~2x 3'11" - 4'3" | ~1,00 - 1,70 / ~3'3" - 5'6" | 1,30 - 2,00 / 4’4” - 6’7” | ~1,00 - 1,70 / ~3'3" - 5'6" | ~1,30 - 2,00 / ~4'4" - 6'7" | ~1,10 - 1,70 / ~3'7" - 5'6" | ~1,60 - 2,10 / ~5'2" - 6'10" | ~1,10 - 1,70 / ~3'7" - 5'6" | ~1,60 - 2,10 / ~5'2" - 6'10" |

| Necessary hydraulic couplers | 1 x single acting 1 x double acting | 1 x single acting 1 x double acting | 1 x single acting 1 x double acting | 1 x single acting 1 x double acting | 1 x single acting 1 x double acting | 1 x single acting 1 x double acting | 2 x single acting 2 x double acting | 2 x single acting 2 x double acting | 1 x single acting 1 x double acting | 1 x single acting 1 x double acting | 2 x single acting 2 x double acting | 2 x single acting 2 x double acting | |

| Working capacity | [ha/h / ac/h] | ~ 3,50 /~ 8,70 | ~ 4,00 / ~ 10,00 | ~4,50 / 11,30 | ~4,90 / 12,30 | ~ 3,50 / ~ 8,70 | ~ 4,00 / ~ 10,00 | ~ 3,50 /~ 8,70 | ~ 4,00 / ~ 10,00 | ~ 3,50 /~ 8,70 | ~ 4,00 / ~ 10,00 | ~ 3,50 /~ 8,70 | ~ 4,00 / ~ 10,00 |

| Number of discs | [pcs.] | 7 | 8 | 9 | 10 | 7 | 8 | 7 | 8 | 7 | 8 | 7 | 8 |

| Number of knives | [pcs.] | 14 | 16 | 18 | 20 | 14 | 16 | 14 | 16 | 14 | 16 | 14 | 16 |

| Tires (with inner tubes) | [pcs.] | 340 / 55 / 16 | 340 / 55 / 16 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 | 400 / 50 / 15 |

| RPM | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | 540 / 1000 | |

| 3-point hitch cat. | II | II | II | II | II | II | II | II | II | II | II | II | |

| Power demand | [HP] | from 80 | from 90 | from 100 | from 110 | from 90 | from 110 | from 100 | from 120 | from 90 | from 110 | from 100 | from 120 |

| Weight | [kg / lbs] | 1702 / 3755 | 1800 / 3970 | 1850 / 4080 | 2050 / 4520 | 2100 / 4630 | 2200 / 4850 | 2480 / 5470 | 2680 / 5910 | 2170/4785 | 2320 / 5115 | 2570 / 5665 | 2710 / 5975 |

| PTO shaft | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | tractor - mower: with friction clutch, built-in: 1. no clutch, 2. with overrunning clutch, 3. with overload clutch, 4. wide-angle u-joint | |

- S - tine conditioner

- W - roller conditioner

- T - transporter

Due to the strategy of constant development ,SaMASZ reserves the right to change technical data at any time and without any notice. All operational data and graphical materials found at our website are for reference only. Some of the equipment items are optional and not included in the standard equipment. For more details concerning warranty, safety and products, please contact your local SaMASZ dealer.

List of dealers: http://www.samasz.pl/en/dealer...

Standard equipment

PerfectCUT cutterbar with quick knife replacement system • SafeGEAR system • hardened slides • wearing plates on sliding skids • support springs • cutting height adjustment • swath width adjustment • metal swath guides (KDC S, ST only) • Belt conveyor (T version) • PTO shaft • additional knives and knife mounting lever • hydraulic cylinders • KENNFIX hydraulic connector • warning plates with LED road lights

Additional equipment

- Standard equipment

- Optional

- —Option not available

| KDC 300 | KDC 340 | KDC 390 | KDC 430 | KDC 300 S | KDC 340 S | KDC 300 ST | KDC 340 ST | KDC 301 W | KDC 341 W | KDC 301 WT | KDC 341 WT | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutting disc with instep | [set] | ||||||||||||

| Topping plates/ Double topping plates | [set] | ||||||||||||

| Rubber swath guide - double (inner) | [pcs.] | — | — | — | — | — | — | — | — | — | |||

| Rubber swath guide - double (outer) | [pcs.] | — | — | — | — | — | — | — | — | — | |||

| Bottom cover of the conditioner | [set] | — | — | — | — | — | — | — | — | ||||

- S - tine conditioner

- W - roller conditioner

- T - transporter

Due to the strategy of constant development ,SaMASZ reserves the right to change technical data at any time and without any notice. All operational data and graphical materials found at our website are for reference only. Some of the equipment items are optional and not included in the standard equipment. For more details concerning warranty, safety and products, please contact your local SaMASZ dealer.

List of dealers: http://www.samasz.pl/en/dealer...

Catalogs